The biggest thing for us since last time is the involvement of British company LMC - generating movement efficiently. - A UK company specialising in the design and production of very high efficiency electric drive trains. With many years experience Trevor from LMC has been a really big help, and we have been able to move ZeroK forward another leap.

When I started this fun project two years ago, I never thought we could achieve so much with very little; it’s been a learning curve. Our last ZeroK version was all about using power aggressively. Now ZeroK takes a different, more elegant approach to the use of energy. After a visit to PFI for testing for karting magazine, a visit to Donnington park and a TV appearance with Tom Wood for BBC news, our chance meeting with Lucas di Grassi’s formula e team manager of ABT Schaeffler inspired us to re-think and ‘go green’, using as little of the precious stuff as possible. Why? Because even with the latest, lightest of all batteries, they’re heavier than petrol, much heavier. It’s a shame there wasn’t a petrol engine with 93% efficiency – you could run for one week on one tank, or enduro race on a cup full. – Smile

Turning our attentions to things that turn.

Working with LMC we now have a very high efficiency motor, weighing just 10.9kg but 92-93% efficient. A truly amazing lightweight simple in design brushed DC motor. Why DC and brushed?, well we looked into several factors- one being cost, and simplicity of operation. At safer, lower voltages aka. 90v and below, DC brushed motors are very good efficiency, lightweight and simple in operation, requiring no extra cooling and wiring bits ‘n bobs.

The brushes last a long time (1500hrs) and cost very little to replace which is a simple DIY process, and the new motor has some special LMC touches than make it run cooler, especially in the brush holder area. Add a new lightweight Laser cut motor mount and a high efficiency belt driver setup with custom CNC rear pulley and it’s a real smooth operator.

The gear ratios are changed by a simple taper lock front pulley, revving much higher our LMC motor required a complete new set of gearing ratios which took some tweaking to get perfect.

Tested at PFI

Runtime single pod average driver weighing 79kg in normal mode 28mins, nearly an hour (about 55mins) with dual pods with a top speed at PFI around 60-65mph.

In Race mode with an experienced driver 15mins single pod, 30mins dual pod top speed 70mph with max acceleration. All driver dependant.

New Battery Arrangement - Allows for an extra set of pods to be clipped in if you want almost double the run time, at the expense of carrying 14% more weight.

Weight has been reduced considerably to 107kg with single pod setup, which is very lightweight for an electric kart.When we hit our final weight we reckon we should be 105kg kart only. Front brakes from OTK added for extra breaking power, along with Vega white tyres and new bearings all round.

New bluetooth and Tablet connectivity - Use your tablet as the driver dashboard. Tablet fits into a shock and water resistant display holder. From here you can touch control the karts settings, view all kart data and log runs etc.

Better weight distribution and a location for all electronics is now within the front nose area making for a clutter free install, and better air flow and weather proofing.

Oh did I forgot to mention the noise? There is now almost no noise from the motor and belt; again less energy lost.

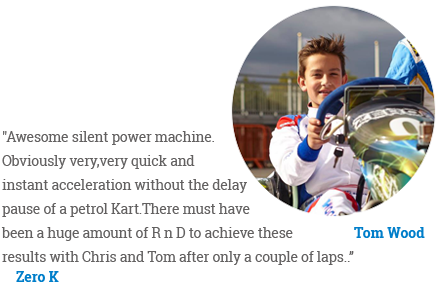

Two talented drivers. Tom Wood and Chris McCarthy - 76MPH Tom, 62sec full track

The result of all this has been a big increase in runtime, handling and breaking. The charging is taking approx. 35mins, and the overall stress on the packs has been reduced somewhat making for healthier cooler running packs and motor. In fact the system is so efficient now that even after 28mins of our testing the powertrain came into the pits just slightly warm to the touch, less than 40 Deg C.

During testing some of the runs around PFI (in total we had about 2hrs 30mins testing time) the averaged out current draw was a little over 36Amps, all the changes above helping to reduce this by nearly 90Amps !

The Future..?

So just imagine if the ZeroK could be made lighter still - with the use of carbon Fibre parts, Composites and maybe a new type of chassis material for electric karts ? Weight plays a big part in this factor too, so maybe weight saving now is the way forward, along with Aerodynamics and regenerative braking and the new battery tech on the horizon from Japan. One things for sure the devils in the detail just like anything its all the small changes that add up to big results. James - ZeroK"