Lynch Motors help to make factory machines more efficient

Background

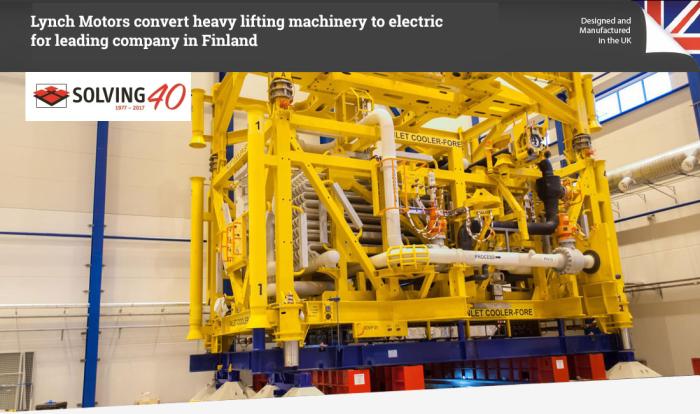

As a world leader in the Automated Handling of Heavy Loads, Solving celebrated 40 years in the industry in 2017. Based in Finland, Solving specialise in the design and manufacture of heavy load handling systems. Solving recently contacted Lynch Motors for two small yet efficient and reliable motors for their newly designed air mover machine.

What we were asked to do

Solving recently produced an air mover machine. Air movers do exactly what it suggests- they move air through friction free movement. Used to perform tasks where cranes and rails simply cannot reach, air moving machines require motors fit to perform as they are intended and are ideal for material handling solutions for assembly lines and inside factory operations.

Our Solution

Lynch Motors worked with Solving to produce the machine which was powered by 2 LEM-130 motors- each one being 3Kw 48v traction motors and weighing in at only 3kg each- to lift an incredible weight of 180 tons.

Requiring motors that offered a more efficient power source, Solving opted for Lynch electric motors as they were also more energy efficient than their current motor, and took up less space. One of the biggest benefits of this type of electric motor is the increased running time and reliability of power for any un-manned machinery within their Finland based premises, increasing efficiency, productivity and reducing any downtime.

With Solving’s need to cover huge loads, regardless of size and movement frequency, the Lynch electric motor ticked all of the boxes.